English

Electric lifting hoists are more labor-saving than manual chain hoists.

Manual chain hoists are mainly driven by manpower, and the gears are driven by hand-pulling chains to drive the weight up. During the lifting process, the operator needs to continuously pull the chain with force, and the pulling force must overcome the gravity of the weight. If the weight is heavy, the pulling force required is large, and long-term operation will make the operator feel very strenuous, easily fatigued, and the work efficiency is also low.

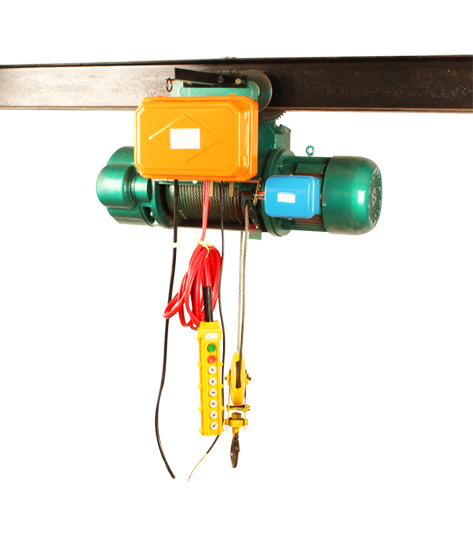

Electric cable hoists use electric motors as power sources. After the motor is powered on, it generates torque, and through transmission devices such as reducers, the power is transmitted to the wire rope or chain, thereby driving the hook to lift the weight. The operator only needs to press the control button, and the electric hoist can automatically complete the lifting action without directly applying a lot of force. Even if lifting heavier objects, electric lifting hoists can complete the task more easily with the power of the motor and the design of the transmission system, which greatly reduces the labor intensity of the operator, improves work efficiency, and has obvious advantages in labor saving.

Electric hoist is highly efficient, labor-saving, and precise, and is widely used in a variety of scenarios:

Industrial production: On the production line of the factory, electric hoists can be used to lift raw materials, semi-finished products, and finished products to achieve rapid transfer of materials between different workstations. For example, in a machinery manufacturing workshop, large parts are lifted to the side of the processing equipment; in an automobile manufacturing plant, they are used to move heavy parts such as automobile engines.

Warehousing and logistics: In the warehouse, electric hoists can be used with shelves to carry out the entry and exit of goods, and can quickly lift the goods and accurately place them in the designated location to improve the efficiency of warehousing operations. Electric lifting hoists are also commonly used in logistics distribution centers to load and unload goods, especially for heavy goods, which electric lifting hoists can easily handle.

Construction: On construction sites, electric hoists can be used to lift building materials such as steel, cement boards, etc., and can also be used to install building components such as prefabricated wall panels, roof trusses, etc. Its precise control performance helps to accurately install components during high-altitude operations and ensure construction quality and safety.

To choose an electric pulley hoist that suits you, you need to consider the following key factors:

Lifting capacity: Choose according to the maximum weight that needs to be lifted. Generally, the lifting capacity of electric lifting hoists ranges from 0.5 tons to 100 tons. Make sure that the rated lifting capacity of the selected electric hoist is greater than or equal to the actual maximum lifting capacity to ensure safety and normal use.

Lifting height: Determined according to the height that needs to be lifted in the work scene. Common lifting heights are 6 meters, 9 meters, 12 meters, etc. Higher lifting heights can also be customized under special circumstances. A certain margin needs to be reserved to meet the maximum lifting requirements in actual work.

Working environment: If you work in a humid, dusty or corrosive gas environment, you should choose an electric lifting hoist with a corresponding protection level. For example, explosion-proof electric hoists are suitable for places with flammable and explosive gases, and anti-corrosion electric hoists are suitable for corrosive environments such as chemicals.

Operation speed: Select the appropriate operation speed according to the work efficiency requirements. Generally, there are normal speed and double speed. The double-speed electric chain fall hoist can use low speed for precise positioning to improve the accuracy and safety of the work.