English

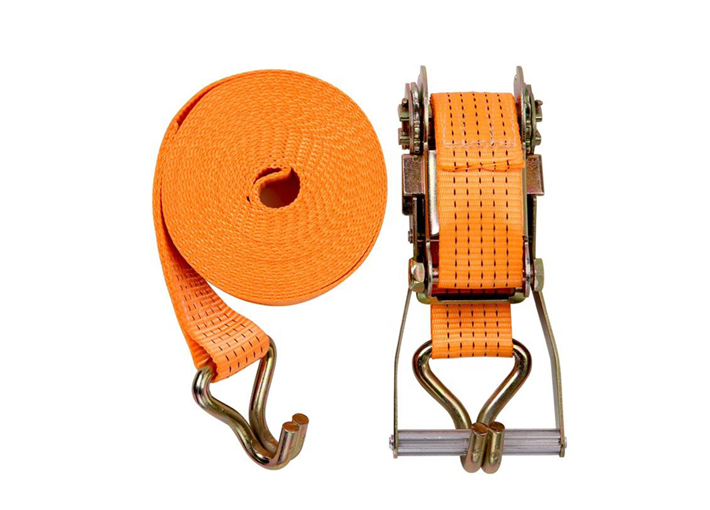

The correct use of Lifting Slings requires standardized operation in many aspects to ensure safety and efficiency:

Preliminary preparation: According to the weight, shape and working environment of the heavy object, select the corresponding specifications and materials of the lifting belt, and its rated load must be higher than the weight of the heavy object. Check carefully before use. If there are problems such as wear, tear, broken wire, softening, aging, etc., replace it immediately to avoid hidden dangers.

Installation and operation: During installation, hang the lifting belt accurately on the lifting point of the heavy object to prevent twisting and knotting, ensure good contact and avoid slipping. The lifting and lowering process must be smooth, avoid sudden acceleration, deceleration or shaking to prevent impact damage. Overloading is strictly prohibited to ensure that the operation is within the rated load range.

Protection and maintenance: When the lifting belt contacts the sharp edge of the heavy object, a protective pad or sheath must be used to prevent cuts. When using multiple lifting belts, ensure that the load is evenly distributed and the angle is reasonable. After use, clean the lifting belt, store it in a dry, ventilated and light-proof place, and check and maintain it regularly.

Lifting slings come in a variety of colors, and different colors correspond to different load capacities, suitable for different scenarios.

White or light-colored lifting belts: Generally, the load capacity is low, usually 0.5 tons or 1 ton, suitable for lifting light items, such as electronic equipment and small furniture, to avoid damage to the surface of items in indoor environments or delicate operations.

Colored lifting belts (such as purple, green, yellow, etc.): Purple is usually 1 ton, green is 2 tons, and yellow is about 3 tons. Purple can be used for lifting small parts; green is suitable for lifting ordinary materials such as gypsum boards in building decoration; yellow can be used for medium-sized equipment in factories, such as the movement and installation of small stamping machines.

Dark lifting belts (such as gray, red, etc.): Gray is generally 4 tons, and red is 5 tons and above. Gray can be used to lift medium-sized components such as steel beams at construction sites; red is used for lifting large equipment, such as lifting containers at ports, and lifting heavy components such as cabins during the installation of large wind power equipment, which can meet the high requirements of large-scale projects for lifting capacity. In short, the lifting belt should be selected according to the actual load-bearing requirements and working environment to ensure safety and efficiency.

To determine whether the lifting sling straps are overloaded, you can start from the following aspects:

Compare the rated load: Carefully check the rated load marked on the lifting sling label or instruction manual to clarify its load-bearing capacity. Accurately weigh the weight to be lifted. If the weight of the weight is close to or exceeds the rated load of the lifting sling, it is likely to be overloaded and lifting is strictly prohibited.

Observe changes in appearance: Check the lifting sling before lifting. If there is damage such as wear, broken wires, and tears, it may affect its load-bearing capacity. If the lifting sling is found to be abnormally elongated, narrowed in width, or obvious indentations appear on the surface during lifting, it is very likely that the material is deformed due to overloading.

Pay attention to the lifting status: If the lifting sling is abnormally tight during lifting, such as tighter than usual and shaking, or if the weight is difficult to rise during lifting, there is a jamming phenomenon, or even it cannot be lifted normally, it may be caused by overloading. In addition, if the lifting equipment (such as a crane) has abnormal sounds or vibrations, it may also indicate that the lifting straps for cranes is overloaded, and the operation should be stopped immediately for inspection.